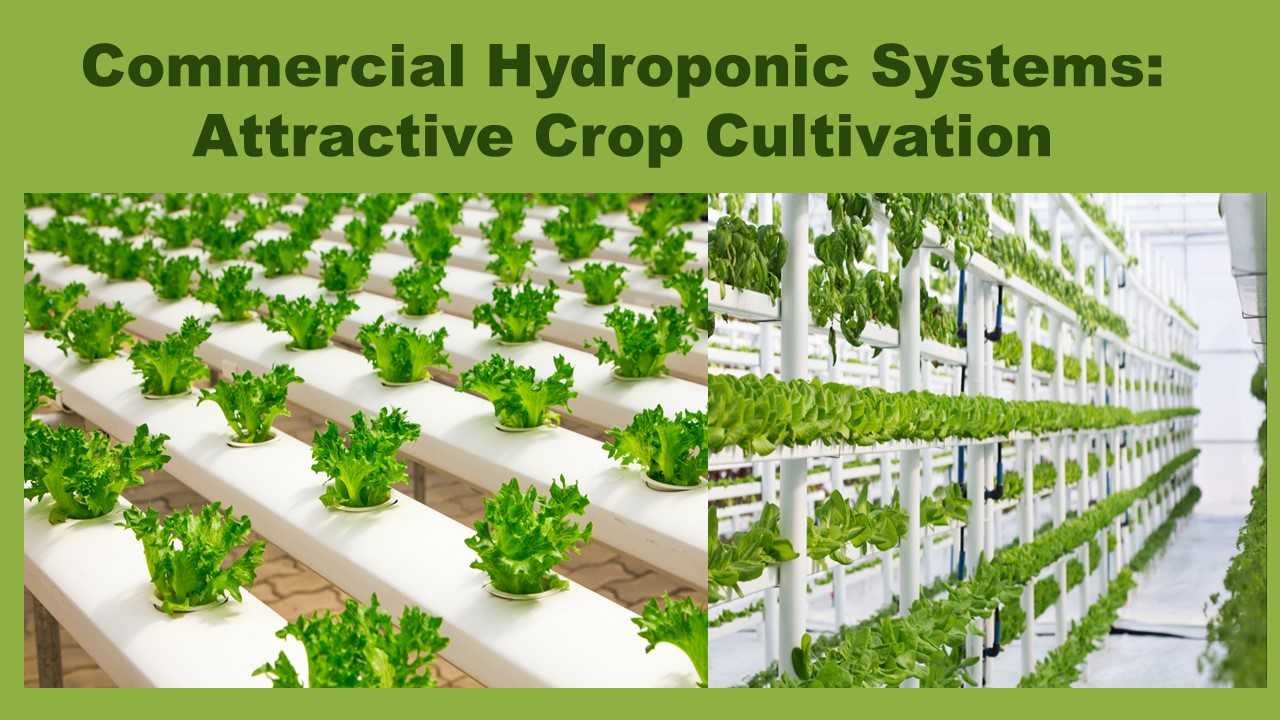

Commercial Hydroponic Systems: Attractive Crop Cultivation

Commercial hydroponic systems have come a long way with the advancement of new technologies every day in each sector, which has contributed to rapid work and swiftness to match the pace of daily life. These techniques in the agriculture sector are through which one can grow more crops in less space and that too by saving water. This system includes growing crops without soil, so the name given to it is “soil-less farming”. In this, the plant’s roots grow in a nutrient-enriched liquid solution (which is composed of essential nutrients) or in moist inert materials like vermiculite and rockwool.

The plant roots are either immersed in a stagnant liquid solution or a continuously moving solution. moreover, commercial hydroponics systems that produce crops on a large scale require the same attention, care, and maintenance that the hydroponic system requires in a single room. In the following article, information about commercial hydroponics systems that are an essential part now for urban farming is taken into account for the growers.

Commercial Hydroponic Sytems Prevalent in India:

Below are the commercial hydroponic systems that are used on a wide scale in India:

- Vertical NFT System

- Horizontal NFT System

- Aeroponic System

- Indoor Grow System

- DWC or RAFT System

- Dutch Bucket Grow System

- Zip Grow System

One by one, we will get to learn about these systems;

1) Vertical NFT System:

It is a kind of active commercial hydroponic systems that makes use of gully channels to grow plants in which nutrient solution flows constantly. It is easy to install and less expensive comparatively due to the low cost of materials. Out of all commercial hydroponic systems, in this more plants can be accommodated because the growing channels are stacked up one over the other in an “A” shape structure. It is slightly higher and produces more yield than flat NFT.

Besides this, it provides an aesthetic, beautiful view suitable for leisure sightseeing. But like every coin has two faces, so same with this commercial hydroponic system too, Its cons include difficulties in setting up technical parameters, a limited range of crops that can be grown by this technique, use of additional LED lamps due to uneven lighting conditions for plants in the bottom row.

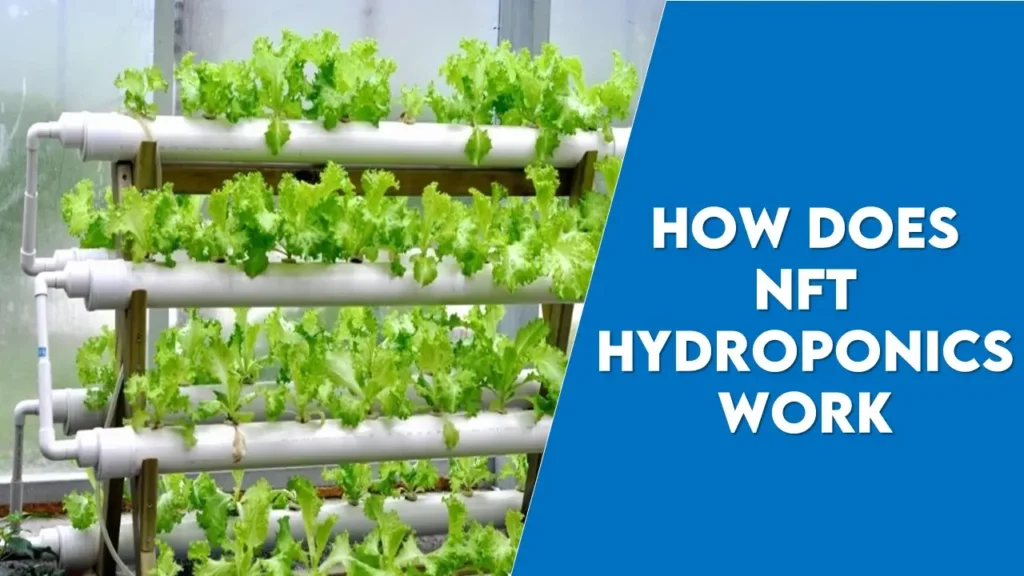

2) Horizontal NFT/Flat NFT Hydroponic System:

The principle behind this horizontal commercial hydroponic systems is the same as for the vertical hydroponic system. This commercial hydroponic system is best suited for larger spaces or areas to have maximum plant growth. It is considered a basic form of NFT systems. It comprises inclined grow channels that receive a continuous stream of nutrient-rich solution which is to be absorbed by the immersed plant’s roots.

The solution is again recirculated into the system and hence the process repeats. It is easier to maintain due to fewer parts in a system along with evenly lighting conditions for plants to grow. It is best suited for plants that are more in height like lettuce, spinach, and basil. This system comes with difficulty in harvesting produce especially in the middle row of the channel.

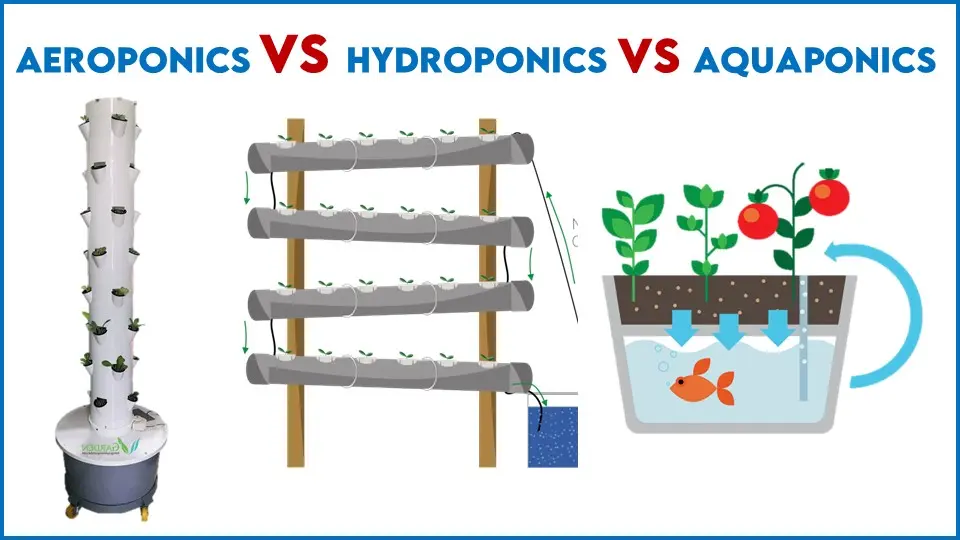

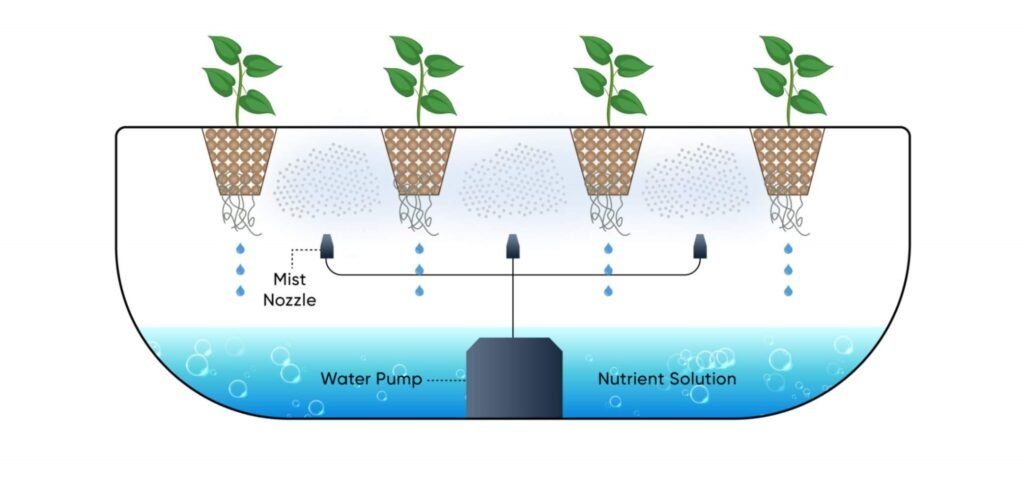

3) Aeroponic System:

As the name indicates, this commercial hydroponic systems requires an air or mist environment to grow plants. It originated from the 2 Greek words: aer (air) and ponos (work). In this, roots are suspended in the air and irrigated with nutrient-dense mist coming from mist heads of size 20-50 micrometers, unlike other systems that make use of liquid solution. Through this system, healthy plants with fast crop growth rates and higher yields are obtained because roots have greater access to oxygen.

In this system, plants are grown in large vertical grow racks and a nutrient-rich mist is directly delivered to the plant root zone. Indoor grow lights of certain wavelengths are used to promote overall plant growth. Plant stress is decreased due to an increase in the nutrient absorption process. Advantages of aeroponics include disease-free cultivation, water, and nutrient hydro atomization. Some others are:

- This system is productive and sustainable

- Air exposure promotes healthy plant growth

- Promotion in photosynthesis

Aeroponic Tower:

It is one of the extensions of commercial hydroponic systems. Agronomy is Europe’s first vertical garden that utilizes aeroponic towers to grow food naturally and conserves 95% of the water that is used in organic farming. It is useful in fulfilling the expanding food demands of the world due to a decrease in the usable farmland for cultivating crops.

4) Indoor Grow System:

This is the most popular system of commercial hydroponic systems among growers who wish to grow fresh produce in their own homes. It is worthwhile in small spaces with natural light. Year-round production of several plants, herbs, and vegetables is possible with this system.

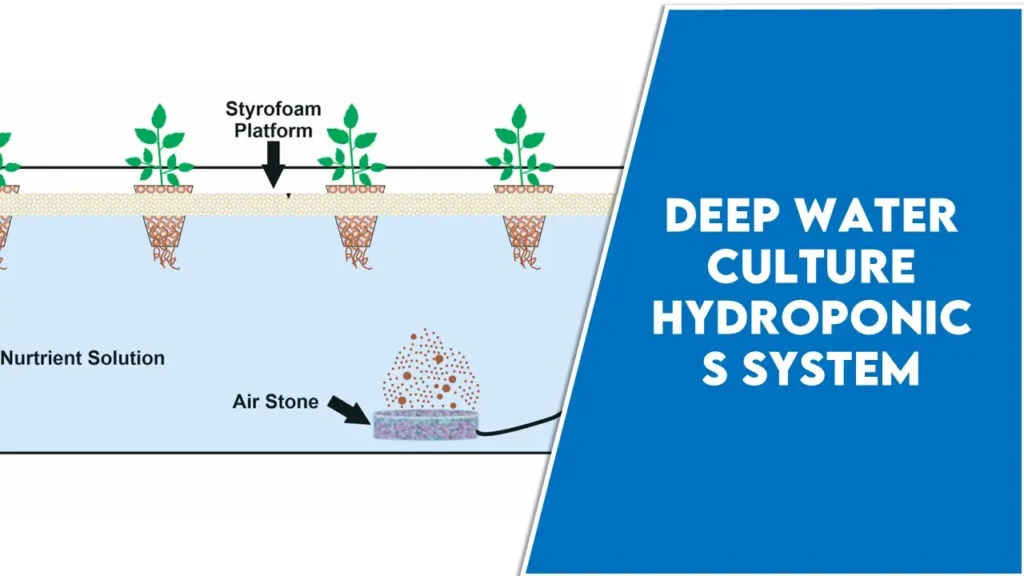

5) DWC or RAFT System:

Also known as RAFT aquaponics system, deep water culture aquaponics, or floating RAFT system. This commercial hydroponic systems uses the basic principles of aquaponics in which fishes are kept in tanks to produce ammonia-rich waste that serves as a natural fertilizer for plants and the plants in turn help purify the water for the fish. Deep water culture allows the roots of the plants to be immersed in water so that they gain enough amount of nutrients. The RAFT system has the subsequent essential components:

- Fish Tank:

Fishes are to be kept in a tank that also provides a favorable environment for fish to survive and produce waste.

- Filtration System:

This filters the solid waste from the water that is coming from the fish tank (through a filtration system).

- Grow Beds:

It contains floating rafts for giving support to plants.

- Floating Rafts:

These provide a buoyant platform to the plants and are generally made up of food-grade materials. They have holes/pockets in them, in which plants are placed with their roots suspended in water.

- Water Pump and Aeration:

The water pump circulates the water from the fish tank to the growing plants, ensuring a constant supply of nutrients.

6) Dutch Bucket Grow System:

This commercial hydroponic system is also known as the Bato Bucket System which makes use of buckets as a growing medium for hydroponically grown crops. There are different sizes of buckets according to the needs of the grower. Bucket, reservoir, pump, and drain pipe are the various components of this system. In these buckets, materials like coco peat, vermiculite, or clay balls are filled that help to hold the roots along with also supply good aeration. Through the drippers, nutrient-enriched medium is supplied to the roots.

A timer is provided with this system so that the optimum amount of nutrient-rich water is supplied to the plant’s roots at regular intervals. Because it separates the medium bed into smaller buckets, this commercial hydroponic system takes a different strategy than all other systems. Plants that have larger roots like tomatoes and cucumbers are grown with a Dutch bucket grow system.

7) Zip Grow System:

This is generally the most effective vertical commercial hydroponic systems in the structure of towers that are specifically designed for high-density hydroponic farming. It hangs to the wall vertically and allows the plant to grow in straight rows. Maximum light and space use efficiency are the key advantages of the zip grow system that make the production double or triple in comparison to other commercial hydroponic systems. Growers may place these towers anywhere they like because they are available in various sizes.

An essential component of this is matrix media which provides roots with an excellent environment and enhances communities of beneficial bacteria. It combines 3 functions: growing media, mechanical filter, and biological filter. It is mostly apt for leafy vegetables like lettuce, chard, kale, cress, bok choi, and mustard greens.

Average Price Range of Commercial Hydroponic Systems:

Before setting up of any commercial hydroponic systems, one should know the exact cost of installation, investing and profit margin for a successful hydroponic system. Price varies and depends upon the size and scale of operation of producing crops. Another cost addition is whether to install additional LED grow lights or not. A 26 ft 9 in x 10 ft 6 in x 31 inch commercial NFT system will cost $3,295. While a 4 ft x 8 ft Ebb and Flow system will cost $1,725.

Although the initial cost of setup installation is high for commercial hydroponic systems the returns are much higher than the traditional crop growing. With the help of these systems, one can grow 3-4 times more amount of produce in the same amount of space.

Advantages and Disadvantages of Commercial Hydroponic Systems:

| Advantages | Disadvantages |

| Higher yield | Initial installation cost is high |

| Reduces the need of herbicide or pesticides | Requires regular monitoring and constant control |

| Low water utilization | Vulnerable to electricity shortages |

| Less contamination | Some chances of contamination by bacteria and moulds in water |

| Adapted to extreme conditions | Knowledge and skillful experience is required |

Conclusion:

From the above article, we get to know the variety of options that commercial hydroponic systems offer, although the underlying principle behind all types remains the same. The most important consideration is the choice of nutrient solution that is being provided to the plants. Also, ensure that a high-quality fertilizer is used in commercial hydroponic systems so that plants will have an enhanced growth rate. Setting up commercial hydroponic systems, if any of the above, saves as much as 10 times water compared to traditional cultivation methods.

For a successful conducting of commercial hydroponic systems, one needs to ensure to follow proper practices like pricing strategy based on value, location, lighting, growing system, learning from the past process, quality farm labor, and passion otherwise, failing in these can make a loss in the venture.

Latest Post

- Nutrients Required for Hydroponic Farming

- Types of Grow Light for Hydroponics

- Factors Affect Nutrient Solution in Hydroponics

- How to Maintain pH and EC in Hydroponics System

- How to Clean Hydroton Clay Pebbles For Reuse

- How to Clean Hydroton Clay Pebbles for Reuse

- Role of Grow Light in Hydroponics

- How to Grow Hydroponic Peppers (Bell Peppers Hydroponics)

- Aeroponics vs Hydroponics vs Aquaponics

Join Our Hydroponics Growers Group!

Connect with fellow hydroponics enthusiasts, share your ideas, ask questions, and grow together as a community.

👉 Join WhatsApp Group